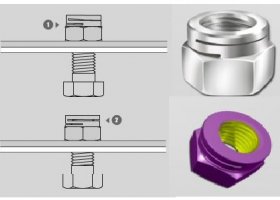

» SLOTTED SELF-LOCKING NUT

The principle of the self-locking nut ESL is to effect a locking on the sides of some threads of the male element on 2 sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values.

During assembly, the collar of the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload.

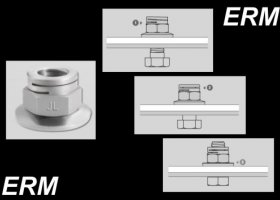

» SLOTTED SELF-LOCKING HEXAGON FLANGE NUT WITH FREE WASHER - ERM

The principle of the self-locking nut ERM is to effect a locking on the sides of some threads of the male element on 2 sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values.

During assembly, the collar of the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload.

The ERM also includes a mobile conical washer which is flattened when assembling through the tension of the male element, under the effect of tightening torque. When phenomena causing a decrease of the tension of the male element, the conical washer is going to give back its own constraint which helps to maintain bolt tension under the most severe conditions.

Recommended for all electrical or security assemblies(case assemblies with multiple parts, stacked assemblies with toothings or racks, assemblies of parts consisting of metals at low hardness or soft materials, assemblies painted, electrical connections, etc.).

» SELF-LOCKING NUT BY DEFORMATION SRF STARNUTS

The principle of the self-locking nut SRF is obtained by deformation of the last nut thread by a 3 or 4 point indentation under a specific load.

During assembly, the screw is subjected to a pressure on the thread of the male element in contact with the distorted nut thread, creating a constant locking torque independent of preload.

The nut SRF has a fixed base providing greater contact surface with the support member providing a broader recovery efforts diffusion.

It can replace the washer under the nut affixed.

» SELF-LOCKING NUT BY DEFORMATION GSL ISO 7042

The principle of the self-locking nut GSL is obtained by deformation of the last nut thread by a 3 or 4 point indentation on the top of the nut under a specific load.

During assembly, the screw is subjected to a pressure on the thread of the male element in contact with the distorted nut thread, creating a constant locking torque independent of preload.

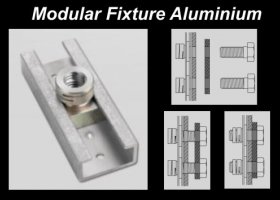

» MODULAR FIXTURES ALUMINIUM

Modular fixtures consist of stainless steel or light alloy channel, in which are mounted self-locking nuts or threaded studs positioned at predetermined distances. Regarding the screws the unloosening of the fasteners is due to the use of self-locking nuts.

Self-locking nuts have a square or rectangular section which is immobilized within the rail and a flange with 2 slots. The principle of the self-locking nuts is to effect on the sides of some threads of the male element on two sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values. During the assembly, the nut returns to its original form generating pressure on the threads which creates a constant locking torque independent of preload.

Modular fixtures allow to quickly report on an overall various fixing points pre-positioned with a certain cross freedom.

Modular fixtures allow for streamlined production and installation of panels, composites, doors and anywhere else. A self- locking adjustable nut is required in single or series.

They easily overcome any differences in critical tolerances when integrating various components.

Costly drill & tap operations are eliminated.

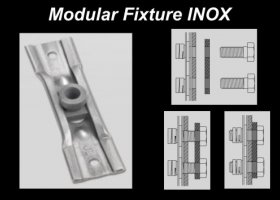

» MODULAR FIXTURES INOX

Modular fixtures consist of stainless steel or light alloy channel, in which are mounted self-locking nuts or threaded studs positioned at predetermined distances. Regarding the screws the unloosening of the fasteners is due to the use of self-locking nuts.

Self-locking nuts have a square or rectangular section which is immobilized within the rail and a flange with 2 slots. The principle of the self-locking nuts is to effect on the sides of some threads of the male element on two sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values. During the assembly, the nut returns to its original form generating pressure on the threads which creates a constant locking torque independent of preload.

Modular fixtures allow to quickly report on an overall various fixing points pre-positioned with a certain cross freedom.

Modular fixtures allow for streamlined production and installation of panels, composites, doors and anywhere else. A self- locking adjustable nut is required in single or series.

They easily overcome any differences in critical tolerances when integrating various components.

Costly drill & tap operations are eliminated.

» NYLON INSERT NUT EUM

The principle of the self-locking nut EUM is a is to crimp a nylon ring at the top of the nut during installation so that the ring deforms around the threads.

The EUM nut also includes a mobile conical washer on its base, which is flattened by the tension of the male element when assembling, under the tightening torque. When phenomena tend to decrease the initial tension of the male element, the conical washer will give back its own compressive constraint and maintain a the tension.

Recommended for all electrical or security assemblies(case assemblies with multiple parts, stacked assemblies with toothings or racks, assemblies of parts consisting of metals at low hardness or soft materials, assemblies painted, electrical connections, etc.).

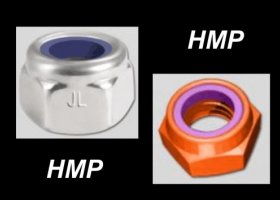

» NYLON INSERT NUT HMP

The principle of the self-locking nut HMP is to crimp a nylon ring at the top of the nut during installation so that the ring deforms around the threads.

Temperature of the ring (to -40 ° C to + 230 ° C peak temperature).

Very low dispersion of the locking torque and constant quality.

» NYLON INSERT NUT HUP

The principle of the self-locking nut HUP is to crimp a nylon ring at the top of the nut during installation so that the ring deforms around the threads.

Temperature of the ring (to -40 ° C to + 230 ° C peak temperature).

Very low dispersion of the locking torque and constant quality.

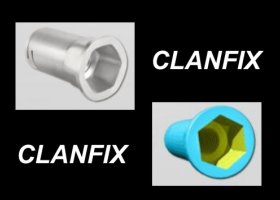

» OTHER PRODUCTS - CLANFIX

The nut CLANFIX is composed of a cylindrical shank and a hex-head ensuring no rotation once installed .

This nut has a triple function: nut, self-locking assembly and rivet assembly.

The CLANFIX functions as a thread on sheet metal with a minimum thickness of 1mm. Suitable for use on all metal and construction of certain composite constructions.

Installation is done blind (access one side). The principle of the self-locking nut CLANFIX is to effect a locking on the sides of some threads of the male element on 2 sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values. During assembly, the collar of the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload.

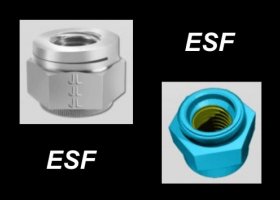

» OTHER PRODUCTS - ESF

The rivet nut ESF should be used to provide threads on sheet metal with thicknesses of 1mm or more. Suitable for use on all metal and construction of certain composite constructions.

The principle of the self-locking nut crimping ESF is to effect a locking on the sides of some threads of the male element on 2 sectors. The plan of the slot is perpendicular of the internal thread axis of the nut.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values.

During assembly, the collar of the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload.

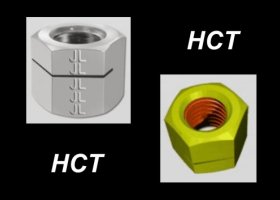

» OTHER TYPE OF SLOTTED SELF LOCKING NUTS - HCT

The principle of the self-locking nut HCT is to effect a locking on the sides of some threads of the male member on a sector of this latter.

This principle is obtained by performing 1 calibrated slot in the central portion the hex nut, which is then crushed under a specific load.

During assembly, the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload